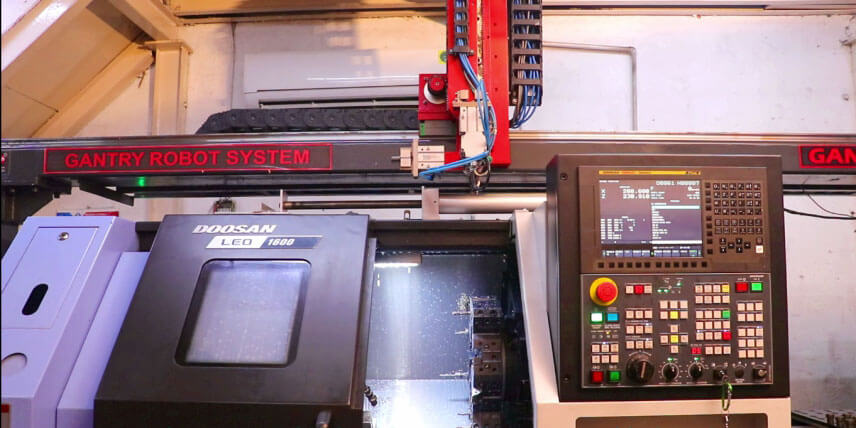

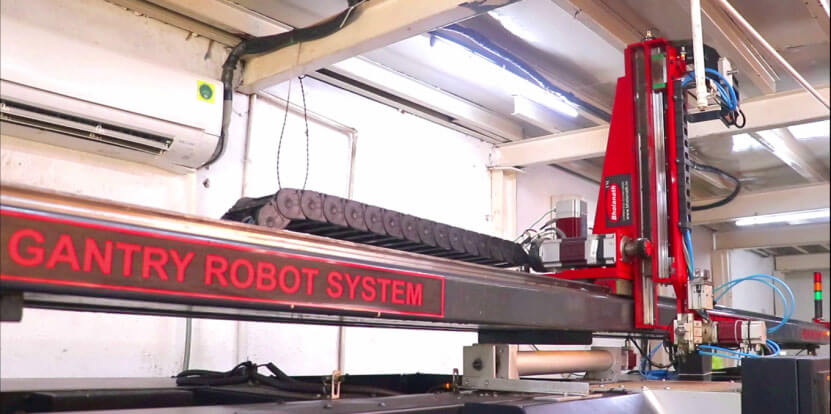

CNC Loading and Unloading Multi Axis Gantry Robot

INCREASE YOUR PRODUCTIVITY BY 35% - 40%.

An Economical high productive CNC automation by Bholanath.

All components like Servo Motors, Servo Drivers, Controller, Linear motion slides (Ball Screw, Rack and Pinion) are all manufactured in-house.

- Trouble Free Operations.

- No Machine downtime like Lunch hour/Teatime/shift change time etc.

- 24 hrs Productivity.

- A single operator can run Minimum of 4 CNC machines.

- Optimum utilization of CNC Machine giving quick return on investment.

- Solves scarcity of skilled labour.

Stepwise operation -

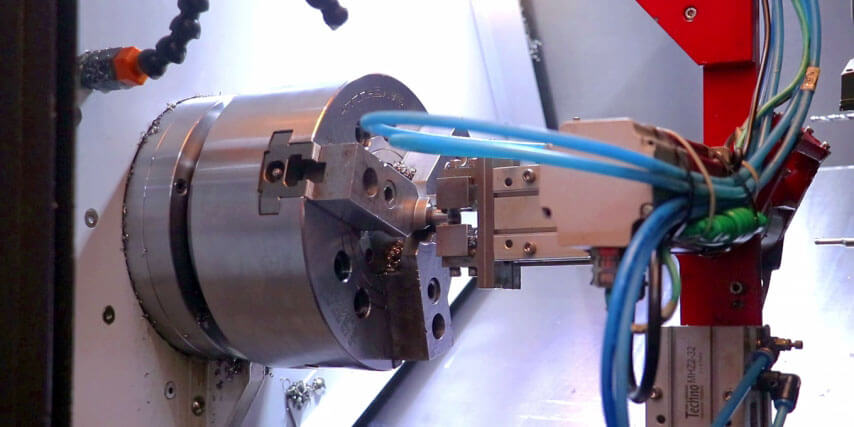

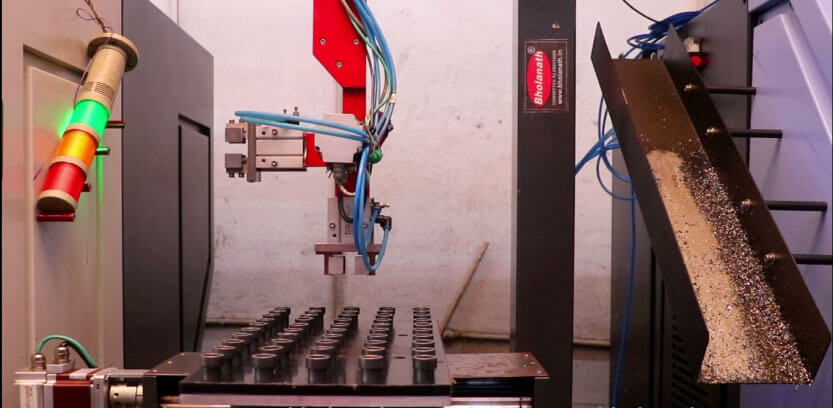

- Picking up component on feeder XY axis.

- Travelling to loading point.

- Automatic Door Opening after machine stops. (Taking inputs from CNC)

- Taking out machined component and placing unmachined component from the CNC chuck.

- Automatic Door Closing, Machine starts. ( Taking inputs from the Gantry Robot )

- Dropping the finished component at designated station. Repeating the cycle.

Case Study - Bholanath has delivered 3 CNC robots for 4 Doosan and Tsugaimi CNC lathe machines at a unit in Mumbai. There were 8 operators in 2 extended shifts of 12 hours. Machine downtime was huge as daily around 9 to 9.5 hrs production was being registered. Also due to frequent labour absentism production capacity was being lost.

Bholanath supplied 2 independent Robots for 2 machines ( Doosan and Tsugami ) and 1 Robot for 2 machines ( Doosan) as same job is being machined. The typical time cycle of all is around 2 minutes.

Due to Bholanath Robots only 2 operators, 1 for each shift is working, thus saving on 6 operators, and 24 hrs production is registered. Thus a very quick return on investment and maximum production is being achieved and capital investment of robots has already been recovered within 6 months.

Are you looking for an economical and highly productive CNC automation solution that can increase your productivity by

35% to 40%? Look no further than Bholanath's CNC Loading and Unloading Multi Axis Gantry Robot.

Bholanath's solution is built with high-quality components like servo motors, servo drivers, controllers, linear

motion slides (ball screw, rack and pinion), all manufactured in-house, ensuring trouble-free operations. With

Bholanath's solution, you can say goodbye to machine downtime during lunch hour, tea time, or shift change time, as it

offers 24-hour productivity. A single operator can run a minimum of four CNC machines, allowing for optimum

utilization of CNC machines and a quick return on investment.

With Bholanath's CNC Loading and Unloading Multi Axis Gantry Robot, you can solve the scarcity of skilled labor. The

stepwise operation of the robot includes picking up components on the feeder XY axis, traveling to the loading point,

automatic door opening after the machine stops (taking inputs from CNC), taking out machined components, placing

unmachined components from the CNC chuck, automatic door closing, machine starts (taking inputs from the gantry

robot), dropping the finished component at the designated station, and repeating the cycle.

Bholanath has delivered three CNC robots for four Doosan and Tsugaimi CNC lathe machines at a unit in Mumbai. Before

implementing Bholanath's solution, the unit had eight operators in two extended shifts of 12 hours, and the machine

downtime was significant, with daily production registering only around 9 to 9.5 hours. Frequent labor absenteeism

further impacted production capacity.

Bholanath's solution supplied two independent robots for two machines (Doosan and Tsugami) and one robot for two

machines (Doosan), as the same job was being machined. The typical time cycle of all is around 2 minutes.

Thanks to Bholanath's robots, only two operators, one for each shift, are working, saving six operators, and achieving

24-hour production. Bholanath's solution helped the unit achieve a very quick return on investment, with maximum

production being achieved, and the capital investment of robots already being recovered within six months.

In summary, Bholanath's CNC Loading and Unloading Multi Axis Gantry Robot is an excellent solution for increasing

productivity, saving labor costs, and optimizing the utilization of CNC machines. Its high-quality components and

trouble-free operations make it a reliable and cost-effective solution for any manufacturing unit.