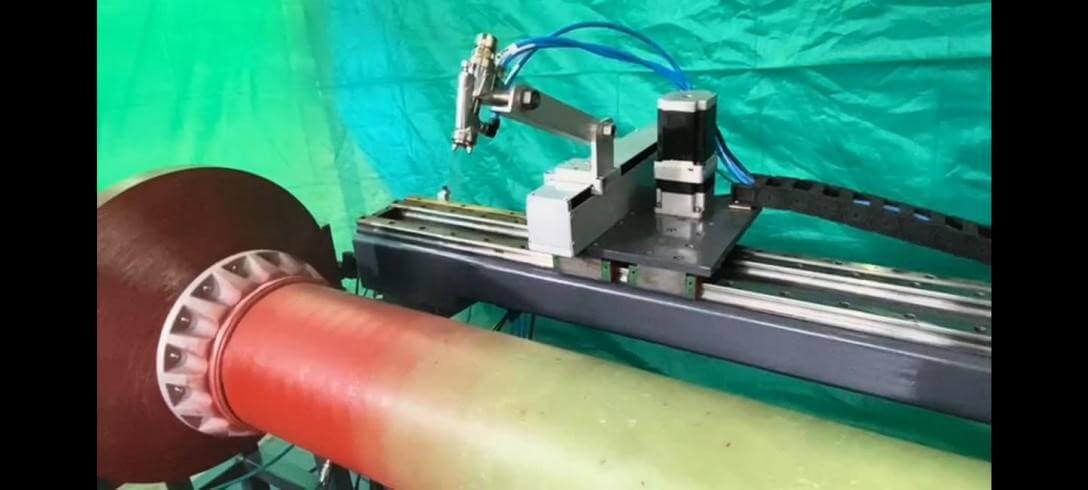

FRP Tube/Pipe Painting Machine

Automatic Tube/Pipe Painting Machine with Spray Gun Arrangement

The Bholanath Automatic Tube/Pipe Painting Machine is equipped with a linear slide mechanism from length 1 mtr to 20 mtr or as per requirement (The Photo shown is 8 mtrs) whose travel speed is controllable, an revolving head stock of which RPM can be controlled and a supporting Tail stock. The linear slide carries an state-of-the-art Spray Gun Arrangement to ensure precise and efficient Tube/Pipe painting. This advanced system is designed to streamline the Tube/Pipe painting process, providing consistent results and minimizing human intervention.

Let's take a closer look at the components of the Spray Gun Arrangement:

-

Control Panel

The system is run by a PLC controlled electrical panel. This has an HMI - Human Machine Interface through which all functions can easily be controlled like - 1. Travel speed of linear movement 2. Rotation speed of head stock 3. Starting and switching off time of spray gun 4. Programming of complete cycle ETC. This is a very simple operator friendly panel which any factory operator can easily operate.

-

Automatic Spray Gun

Our Automatic Spray Gun features a 1.3mm Nozzle hole, which allows for precise and uniform paint application. This nozzle size is optimized for the best painting results, ensuring that Tube/Pipes are coated evenly and efficiently.

-

Pressure Tank

The machine is equipped with a 9-liter stainless steel (SS) body pressure tank. This tank is designed to store and supply the necessary pressure to the spray gun, ensuring a continuous and consistent paint flow.

-

Filter - Regulator Unit for Incoming Air

To maintain the quality of your painting process, the system includes a filter-regulator unit for incoming air. This unit filters and regulates the air supply to remove impurities and control the air pressure, ensuring clean and consistent painting.

-

Pressure Regulator and Gauge for Paint Tank

A pressure regulator and gauge for the paint tank are integrated into the system. These components help you maintain the ideal pressure level within the tank, enabling precise control over the paint application process.

-

Pressure Regulator and Gauge for Atomising Air

For atomizing air, the machine includes another pressure regulator and gauge. This ensures that the atomizing air is maintained at the right pressure for optimal paint atomization and coverage.

-

Additional Flexible Piping

To provide flexibility in your setup, the Bholanath Automatic Tube/Pipe Painting Machine includes 20 meters of additional flexible piping that connects your compressor to the spray gun. This extended reach allows for versatility in your workspace and accommodates various Tube/Pipe painting requirements.

-

MS Stand

All ancillary equipment and the pressure tank are securely mounted on a robust MS (Mild Steel) stand. This stand ensures stability and ease of use, making it convenient to position the machine in your workspace.

The Spray Gun Arrangement of the Bholanath Automatic Tube/Pipe Painting Machine is a reliable and efficient solution for your Tube/Pipe painting needs. With its precision components and user-friendly design, it enhances productivity and delivers consistent, high-quality results. Whether you're working on a small-scale project or a large industrial application, this system is designed to meet your needs.